|

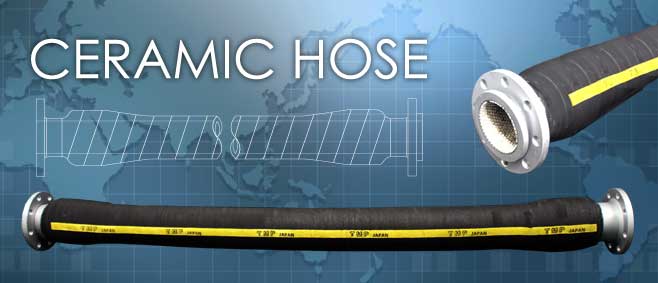

| The flexible pipes or hose are lining with ceramics balls are used to reduce the internal costs.However,the TMP developed the ceramic tile in the form of pressure wich has five times longer useful life.Another adavantage with respect to flexibility,wich my curve in the same proportion. |

| In the newly developed ceramic hose, ceramic tips

are used to eliminate a disadvantage in a conventional ceramic hoses. It has

higher abrasion resistance while maintaining flexibility. The standard

producible ceramic hose is limited to 10 m in length and 30 to 300 mm in hose

diameter. |

| In the newly developed ceramic hose, ceramic tips

are used to eliminate a disadvantage in a conventional ceramic hoses. It has

higher abrasion resistance while maintaining flexibility. The standard

producible ceramic hose is limited to 10 m in length and 30 to 300 mm in hose

diameter. |

| An elbow type ceramic hose is available. We can

produce a hose in a customer's design. Our new ceramic hose has the circular

disk shaped ceramic tip as compared with the conventional ball shaped ceramic

tip and shows several times higher abrasion resistance. |

| Normally, the producible length is 10 m for a

ceramic hose. Please contact with us if you need a longer ceramic hose. In

addition, we can produce a ceramic hose as a customer wishes. If you don't know

the desired dimension, we can produce the ceramic hose having the same

dimension with the existing hose |

The right selection means choosing a product suitable for technical requirements

of certain application or device along with assurance of safe and faultless

performance.Due to above mentioned reasons,we advise to choose the right

lining hose with the help of sales or TECHNICAL department.(kazuo meguro)

expertise.

Essential information for the right lining hose selection;

* Medium (substance conveyed).

* Internal diameter.

* Maximal working pressure;

* Temperature(inside and outside the hose);

* All other features that may effect the hose performance and life such as;vibrations,deformations

during work,exposure for externaldamage,etc..,

* Kind of hose endings(type of fitting,thread size,type of sealing);

* Way of assembling the hose fittings(clip,band,clamp);

* Lenght of the hose (in case of a hose assembly the complete lenght

along with fittings);

|

|