|

|

|

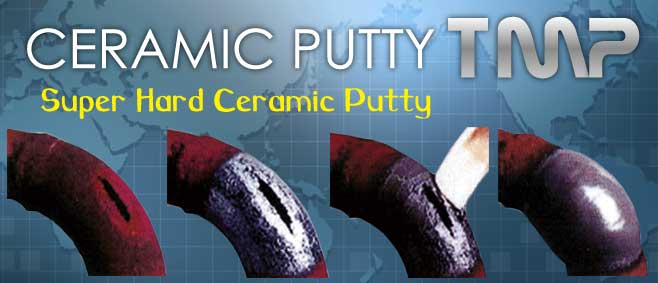

In the application of ceramic putty, (crushed)

ceramic particles is bound and hardened by resin at high density. The lined

ceramic putty can be hardened almost as hard as ceramic itself. You can

increase abrasion resistance by applying the ceramic putty. A large portion of

a slurry pipe, regardless of dry or wet, cannot avoid abrasion. Significant

abrasion is found on a curved portion of a pipe, an inner surface of a dust

collector, an inner surface of slurry sand pump, a hopper, a shoot, a return

roller for a belt conveyor, etc. To protect from abrasion by steel, most of

them are lined with a harder material such as special steel and ceramic on the

surface of the significant abrasion. The abrasion measures have many problems

in cost, an application surface, a secondary maintenance, etc. The ceramic

putty can solve those problems. It is a ceramic material that is a mixture of

abrasion resistance ceramic particles and resin and can be applied easily. |

| In the above application example, the ceramic putty

is applied to fix a hopper. It can be spread from the outside. As compared to

conventional putty, its hardness is much higher and its applicability is

improved. The ceramic putty has sufficient capability to be used for an

emergency treatment until a periodic inspection in a factory |

|

|

An inner surface of a dust cleaner suffers abrasion and its replacement

requires considerable cost.By fixing the abrasion with the putty, it can

prolong the service life of the dust cleaner at low cost.

|

| How to apply ceramic putty |

| |

|

1. Clean up the surface where you will apply the ceramic putty with

toluene, etc.

2. Prepare the surface with a sander, etc.

(Make sure to prepare the surface very well; otherwise, the putty won't

adhere properly.)

3. Take a required amount of the putty and hardener in a mixture ratio

of 2:2.

|

4. Mix them until evenly blended.

5. Apply the putty on the surface smoothly with a spreader.

6. Wait for it to harden, and then hit the application surface with a hammer

to check for the quality. |

| How to apply ceramic putty |

| |

|

1. Clean up the surface where you will apply the ceramic putty with

toluene, etc.

2. Prepare the surface with a sander, etc. (Make sure to prepare the

surface very well; otherwise, the putty won't adhere properly.)

3. Take a required amount of the putty and hardener in

a mixture ratio of 2:2

|

|

4. Mix them until evenly blended.

5. Apply the putty on the surface smoothly with a spreader.

6. Push the putty into a gap with hand.

|

|

7. Wait for it to harden. You can harden the putty quickly by heating

it with a jet heater.

8. Completed.

|

|